In the field of plastic bottle manufacturing, an efficient and precise antifreeze Jerry Can bottle extrusion blow molding machine is becoming the first choice of many manufacturers. This machine has brought a new revolution to the production of plastic bottles with its excellent performance, reliable quality and flexible applicability.

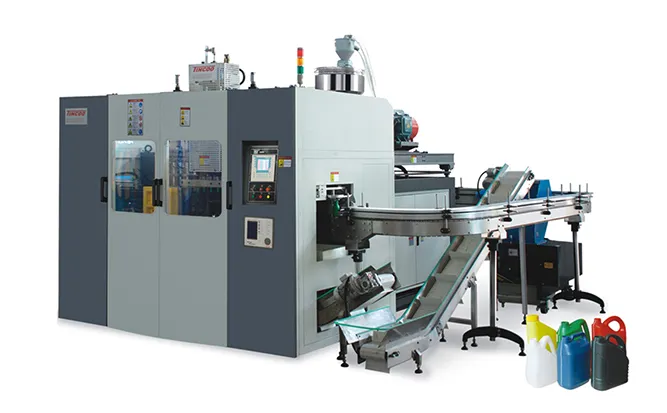

This antifreeze jerry can bottle extrusion blow molding machine adopts advanced extrusion blow molding technology, which can efficiently process plastic raw materials into antifreeze bottles of various specifications. Its design principle is based on the perfect combination of extrusion molding and blow molding. First, the molten plastic raw material is extruded through the extruder to form a tubular blank, and then the blank is blown into a bottle of the desired shape through a blow molding mold. The whole process is highly automated and easy to operate, which greatly improves production efficiency.

In terms of material selection, this machine supports the processing of a variety of plastic raw materials, such as HDPE, which have good antifreeze and corrosion resistance and are very suitable for the manufacture of antifreeze bottles. At the same time, the machine also has a multi-layer co-extrusion function, and can customize bottles with different layers according to customer needs to meet the requirements of plastic bottle performance in different fields.

In terms of performance, this antifreeze jerry can bottle blow molding machine has significant advantages. Its extrusion system has been optimized, and the screw, barrel and other components are made of high-quality alloy materials, which have good wear resistance and long service life. At the same time, the machine is equipped with an advanced temperature control system, which can accurately control the temperature of plastic raw materials during extrusion and blow molding to ensure the molding quality and stability of the bottle.

In addition, this machine also has an intelligent control system. It adopts advanced PLC control system and touch screen human-machine interface, which is easy and intuitive to operate. Users can easily set various parameters, such as extrusion speed, blow molding pressure, etc., to achieve the production of bottles of different specifications. At the same time, the machine also has fault alarm and fault diagnosis functions, which can monitor the operating status of the machine in real time to ensure the smooth progress of the production process.

In terms of application fields, this antifreeze jerry can bottle blow molding machine has a wide range of application prospects. In addition to being used to manufacture antifreeze bottles, it can also be used to manufacture plastic bottles of various specifications, such as food bottles, medicine bottles, cosmetic bottles, etc. Its efficient and precise manufacturing capabilities can meet the needs of different industries for plastic bottles.

In short, this antifreeze jerry can bottle extrusion blow molding machine has excellent performance, reliable quality and flexible applicability. Whether in terms of production efficiency, product quality or cost control, this machine has shown significant advantages.

Copyright © 2024 Tincoo (Changxing) Packaging Technology Co., Ltd. All rights reserved. WEB DESIGN:Morndesign