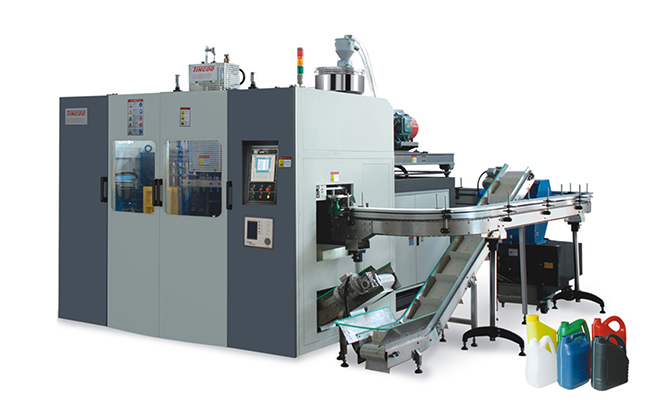

Today, with the rapid development of the plastic packaging industry, the fully automatic HDPE plastic liquid soap bottle extrusion blow molding machine, with its efficient, stable and intelligent features, has brought unprecedented convenience to liquid soap manufacturers and helped the industry upgrade.

The fully automatic HDPE plastic liquid soap bottle extrusion blow molding machine adopts advanced extrusion blow molding technology. After the HDPE plastic raw material is melted at high temperature, it is extruded through a precision mold, and then cooled by blowing air to finally make a liquid soap bottle with regular shape and high quality. The entire process realizes automated control, improves production efficiency and reduces labor costs.

In addition, the machine offers a high degree of flexibility. Whether it is liquid soap bottles of different specifications or various customized design needs, it can be easily handled. This allows manufacturers to create unique products based on market demand and consumer preferences.

It is worth mentioning that this machine also has excellent performance in environmental protection. It uses environmentally friendly HDPE plastic raw material, which is not only non-toxic and harmless, but also recyclable. At the same time, the machine itself also adopts an energy-saving design, reducing energy consumption and contributing to the sustainable development of the enterprise.

The fully automatic HDPE plastic liquid soap bottle extrusion blow molding machine also does an excellent job in intelligence. It is equipped with advanced control systems and monitoring equipment, which can monitor various parameters in the production process in real time to ensure the stability of product quality. At the same time, the machine also has fault diagnosis and automatic adjustment functions. Once an abnormality is discovered, it can respond quickly to avoid production accidents.

In short, the fully automatic HDPE plastic liquid soap bottle extrusion blow molding machine has become a leader in the liquid soap packaging industry with its characteristics of high efficiency, stability, intelligence and environmental protection. Its emergence not only improves production efficiency and reduces costs, but also provides liquid soap manufacturers with more innovation opportunities and market competitiveness. We believe that in the near future, this machine will be widely used in more fields, bringing a better future to the entire plastic packaging industry.

Copyright © 2024 Tincoo (Changxing) Packaging Technology Co., Ltd. All rights reserved. WEB DESIGN:Morndesign