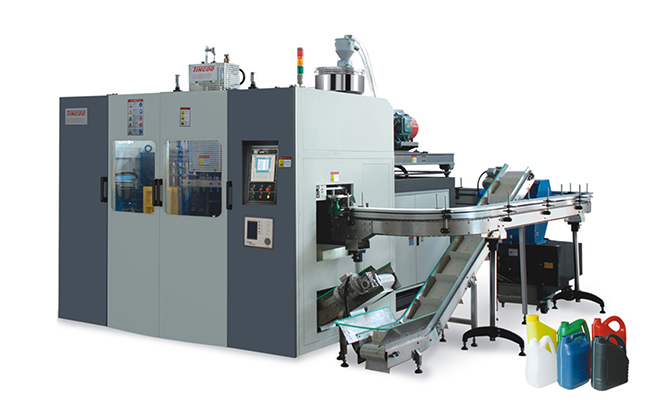

Innovation in the future, High Speed Automatic Blowing HDPE Plastic Jerry Can Production Blow Moulding Machine to lead the industry new fashion

In the plastic packaging industry, technological innovation and upgrading has been the core driving force to promote the development of the industry. today, We introduce a high-tech product that leads the new fashion of the industry – High Speed Automatic Blowing HDPE Plastic Jerry Can Production Blow Moulding Machine (hereinafter referred to as “blow moulding machine”).

This blow molding machine with its high-speed, automatic, efficient characteristics, has become the new darling of the plastic packaging industry. It uses advanced blow molding technology to achieve high-speed production of HDPE (high density polyethylene) plastic Jerry cans, which greatly improves production efficiency and reduces production costs.

1、high-speed production to meet market demand

In the fast-paced modern life, the market demand for plastic packaging products is growing. With its high-speed production characteristics, this blow molding machine can complete the production of a large number of Jerry cans in a short time, effectively meeting the needs of the market. Whether it is a large production enterprise or a small processing plant, it can achieve efficient production and enhance market competitiveness through this machine.

2、 automatic operation, reduce labor costs

Traditional plastic packaging production methods often require a lot of manual participation, which is not only inefficient, but also costly. This blow molding machine uses an automated operation design, with simple setup and adjustment, it can achieve fully automated production. This not only greatly reduces labor costs, but also improves the stability and reliability of production.

3、 high efficiency and energy saving, environmental protection and green

With the increasing awareness of environmental protection, green production has become the development trend of the industry. This blow molding machine in efficient production at the same time, also pay attention to energy conservation and environmental protection. It adopts advanced energy-saving technology, which can effectively reduce energy consumption and reduce the impact on the environment. At the same time, the Jerry cans made of HDPE materials also have good recyclability, which is in line with the concept of green environmental protection.

4、 leading technology, excellent quality

This blow molding machine adopts advanced technology and exquisite workmanship to ensure the quality and stability of the product. In the blow molding process, the machine can precisely control the temperature and pressure, making the product more uniform and beautiful. In addition, the machine also has the automatic detection and alarm function, once the abnormal situation is found, it can stop in time and issue an alarm to ensure production safety.

5、Wide application and broad prospect

Because this blow molding machine has the advantages of high speed, automatic, efficient, environmental protection, etc., it is widely used in food, chemical, medicine and other industries. Whether it is used to store liquid or solid items, it provides quality packaging solutions. With the continuous progress of technology and the continuous expansion of the market, the application prospect of this blow molding machine will be broader.

In short, High Speed Automatic Blowing HDPE Plastic Jerry Can produce Blow Moulding Machine with its excellent performance and a wide range of application fields, has become the new darling of the plastic packaging industry. Its emergence not only promotes the progress and development of the industry, but also brings more convenience and benefits to the majority of users. It is believed that in the near future, this blow molding machine will play a greater role in more fields, bringing more beauty and convenience to our lives.

Copyright © 2024 Tincoo (Changxing) Packaging Technology Co., Ltd. All rights reserved. WEB DESIGN:Morndesign