Machine Manufacturing: A New Chapter in Plastic Barrier Blow Molding Machines

With the rapid development of technology, machine manufacturing has gradually become the mainstream in modern industrial production. In the field of plastic product manufacturing, plastic barrier blow molding machines are leading a new revolution.

At busy traffic intersections, we often see plastic barriers used to divert traffic and prevent accidents from occurring. These seemingly ordinary plastic roadblocks actually conceal precise manufacturing processes behind them. And all of this can be attributed to the plastic roadblock blow molding machine.

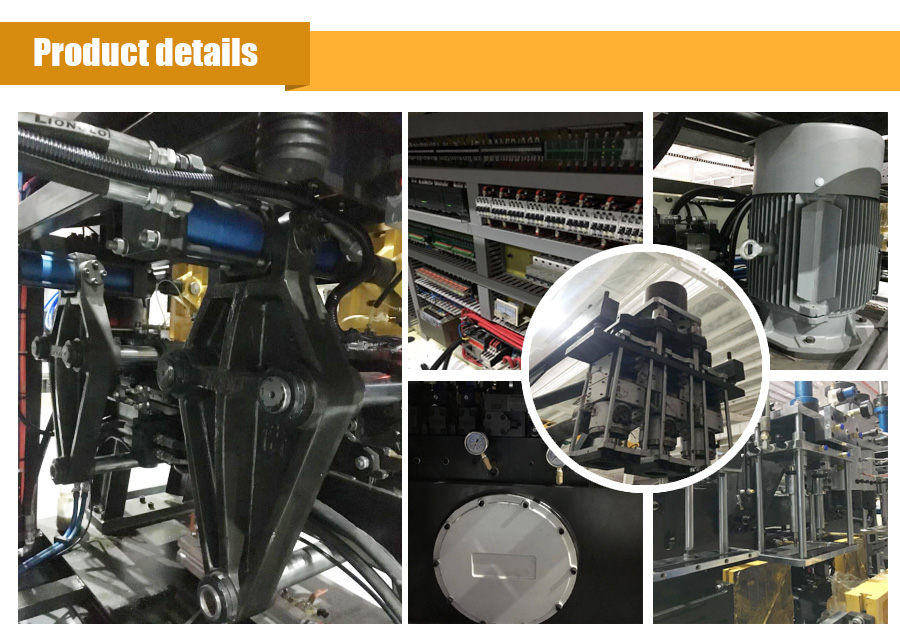

Plastic roadblock blow molding machine is an advanced machine manufacturing equipment that uses high temperature and pressure to melt plastic raw materials, and then uses blow molding technology to blow the melted plastic raw materials into various shapes of roadblocks. This machine manufacturing method not only improves production efficiency, but also ensures product quality and consistency.

Blow molding machine is a molding equipment that processes plastic raw materials through heating, blowing, pulling, and cooling to produce various hollow containers. Compared to other plastic molding processes, blow molding machines have the following advantages:

High production efficiency: The blow molding machine adopts a continuous molding method, which can quickly and efficiently produce a large number of hollow containers, improving production efficiency.

Wide application range: Blow molding machines can produce hollow containers of various shapes and specifications, such as bottles, cans, barrels, etc., with a wide range of applications.

Low cost: The blow molding machine uses plastic raw materials through heating and blowing processes, resulting in relatively low manufacturing costs and high production efficiency, reducing the cost of individual products.

Strong Customizability: Blow molding machines can customize hollow containers of different specifications and shapes according to customer needs, meeting their personalized needs.

In summary, as a plastic molding process, blow molding equipment have advantages such as high production efficiency, wide applicability, low cost, high degree of automation, stable product quality, and strong customizability. They are widely used in packaging, chemical, medical and other fields.

Copyright © 2024 Tincoo (Changxing) Packaging Technology Co., Ltd. All rights reserved. WEB DESIGN:Morndesign