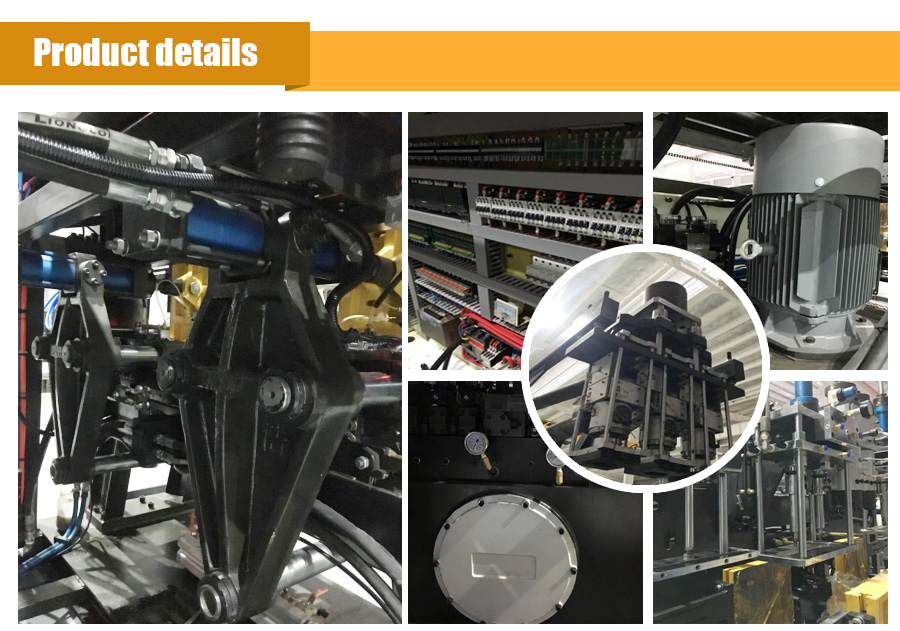

Plastic barrel extrusion blow molding production line this production line integrates three core technologies: polymer material science, precision mechanical engineering and intelligent control systems. Through the integration of extrusion molding and blow molding processes, efficient production from raw materials to finished products is achieved.

1. High efficiency and energy saving, cost reduction and efficiency improvement

The plastic barrel extrusion blow molding machine adopts an intelligent temperature control system and a dynamic energy-saving algorithm to accurately control the extrusion and blow molding temperatures, reducing energy consumption by more than 20%. The modular design supports rapid mold change and shortens the production cycle by 30%. Meet the needs of large-scale orders.

2. Precision manufacturing, excellent quality

Equipped with high-precision sensors and closed-loop feedback control systems. Real-time monitoring of wall thickness and dimensional deviation, and high qualified rate of finished products. Multi-layer co-extrusion technology can realize the compounding of barrier layer, reinforcement layer and outer layer materials. Improve the corrosion resistance and impact resistance of the barrel body and extend the service life.

3. Green and environmentally friendly, sustainable development

The production line fully supports the processing of food-grade materials (such as HDPE, PP) and recyclable plastics (rPET, rPP), reducing dependence on primary resources; the residual material recycling system realizes 100% reuse of scraps and reduces carbon emissions; the low noise and low dust design complies with the EU CE and US FDA environmental protection standards.

Scenario application

Chemical industry: 200L large-capacity plastic barrels meet the sealing and corrosion resistance requirements of dangerous goods transportation;

Food and beverage: customized bottle design, support aseptic filling, and extend product shelf life;

Agricultural field: anti-UV coating treatment, suitable for outdoor storage of pesticides and fertilizers;

New energy industry: lightweight design helps lithium battery electrolyte packaging and improves transportation safety.

The future is here

Facing the “dual carbon” goal and the era proposition of circular economy, plastic barrel extrusion blow molding production line is not only a piece of equipment, but also a “green engine” for enterprise transformation and upgrading. It is driven by technological innovation and has sustainable development as its mission, helping enterprises achieve:

✅ Cost leadership: reducing unit energy consumption and labor costs;

✅ Quality breakthrough: meeting the stringent requirements of the high-end market for packaging;

✅ Brand value-added: enhancing the social image of the enterprise through environmental certification;

✅ Future layout: seizing the opportunity of recyclable material application and intelligent manufacturing.

Copyright © 2024 Tincoo (Changxing) Packaging Technology Co., Ltd. All rights reserved. WEB DESIGN:Morndesign