Double station with high-speed, advanced technology from America and European contries Dry cycle stroke is 700mm, double station only takes 3.8s, 10 heads, multi-layers, fully automatic For use in packaging of 100ml-15000ml washing, cosmetics, food and petroleum containers.

Output: 10,000 to 30,000 bottles/h

Bottle size: 0.25L to 2L

Suitable for: non-carbonated and carbonated

water, soft drinks, juice, tea, isotonic beverage, milk and dairy products,

beer and sauces and HPC products

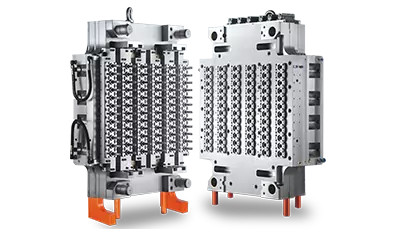

High speed preform production system allows

you gain the same level of specification as European machine but with lower

investment cost at the same time. The system can produce with the preform

injection system can produce with the preform injection molds up to 144 cavities

which including double screw design high speed injection machine precision

preform injection molds, post cooling, take out robot, centralized control

system and high efficient material drying system. The results are higher

production efficiency and better preform quality. You can also choose MHT

preform injection molds from Germany at the same time.

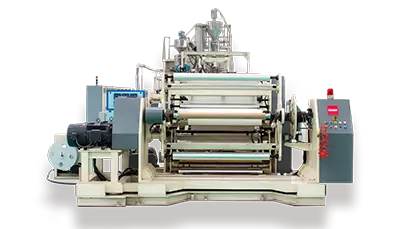

Stone plastic paper uses raw material is mainly

calcium carbonate and other inorganic powder and synthetic resin, non-toxic,

tasteless, no pollution, save a lot of trees and water

Widely used, not only can replace the

traditional wood pulp paper, and ink absorbency is good, water proofing

property, folding and blinding

Alternative non-transparent PVC,PP,PE,PETM

plastic film, reduce cost, suitable for all kinds of bags, shopping bags,

handbags, and its lunch box, cup, dish and so on the disposable products

Copyright © 2024 Tincoo (Changxing) Packaging Technology Co., Ltd. All rights reserved. WEB DESIGN:Morndesign